Flax

Flax is a plant with modest needs, but it does need specific climate conditions. The fibre thrives best in maritime climates with its constant alternation of sun and rain coupled with lots of wind. The plant is sowed in March, from June it transforms the landscape into a sky blue sea of delicate flowers. Optimal conditions for flax cultivation can mainly be found in the coastal areas of northern France and Belgium. The world’s most delicate linen fibres are produced here. As we only use the highest quality raw materials, we only use linen yarns made from flax grown in these regions.

Harvest

When the plants are fully developed, harvesting begins. Flax isn’t cut off, rather it is pulled out of the ground along with its roots. After that, the plants are laid out in the field. The so-called dew-retting process begins: the alternation of sun, dew and rain and the help of bacteria and fungi from the soil expose the fibres hidden inside. Dew-retting is an environmentally friendly process as the nutrients are reabsorbed by the soil during the process.

Processing

After the retting process, the flax is fluted, meaning that the stalk is separated from the seeds. After that, the flax straw needs to be dried again so that the wooden parts of the stalk can be more easily bent and the final impurities can be removed during the further treatments - such as ginning, breaking, scutching and heckling. Only after all these steps can the flax fibres be processed into yarn in the spinning mill.

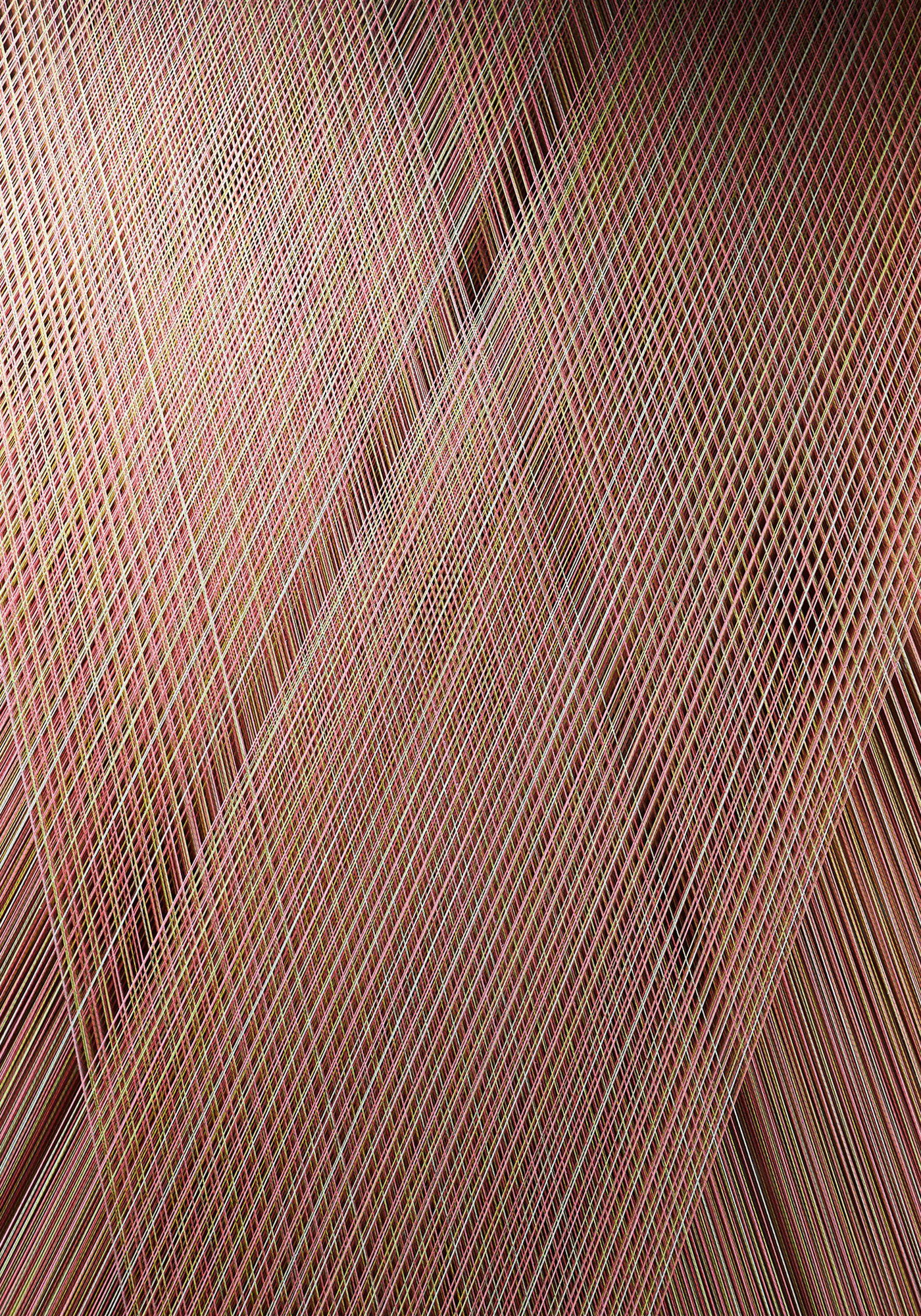

Before weaving

The individual strands are arranged into a so-called warp. Up to 12,800 strands are unwound parallel to each other, with an unrivalled strand density of 40 threads per centimetre. In order to be able to weave these threads later, they are then smoothed - the warp passes through a starch bath, which gives the individual threads a protective layer to withstand friction and tension.

Jacquard

Jacquard is a speciality of the weaving trade - a method for weaving particularly elaborate, richly decorated and detailed patterns. In this technique, each of the thousands of threads can be individually controlled. The fabrics are completed during the subsequent refinement process.

Natural fibres

Natural fibres, especially linen, require considerate production methods. The weaving mill is dampened in order to provide the perfect conditions for processing the fibre. Even the weaving machine needs to be patient: our linens are woven many times slower than other materials, otherwise, the fibres would tear.