Celebrating 170 years

2023 marks the 170th anniversary of our linen manufactory. Find out more about the history of our company.

Read more

The 2023 catalogue

The new catalogue: step into the world of Leitner Leinen and dicsover the 2023 novelties as well as some of our collection classics.

Download catalogue

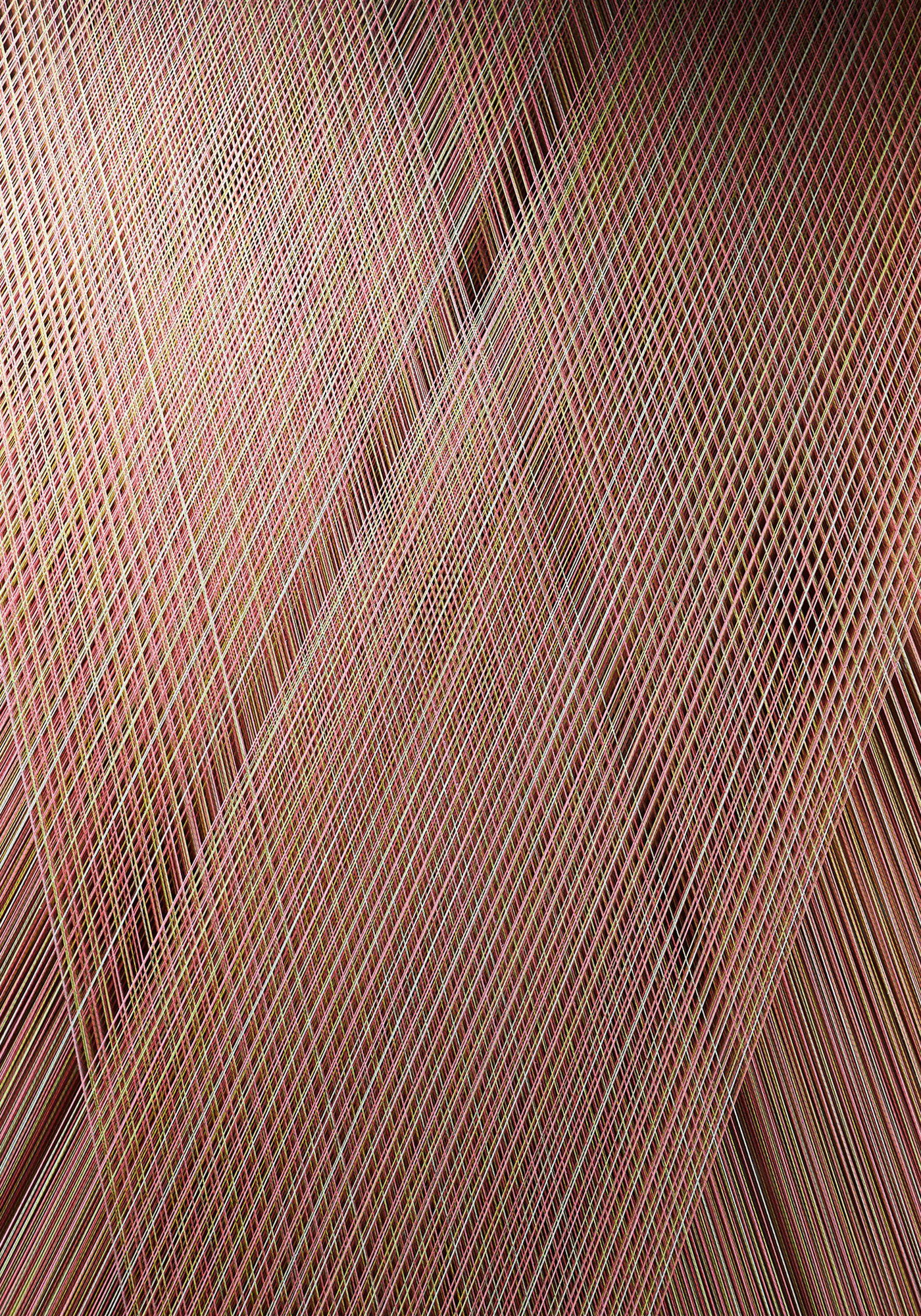

Fleur Royale

We are welcoming spring with floral abundance and historical charm. Discover Fleur Royale, the new design made from 100% linen.

Read more

Fall/Winter 2023

Discover the spectacular 2023 Fall/Winter collection – now available.

Discover the novelties

The 2023 winter catalogue

Indulge in sceneries full of atmosphere and discover our fall and winter product collections.

Download catalogue